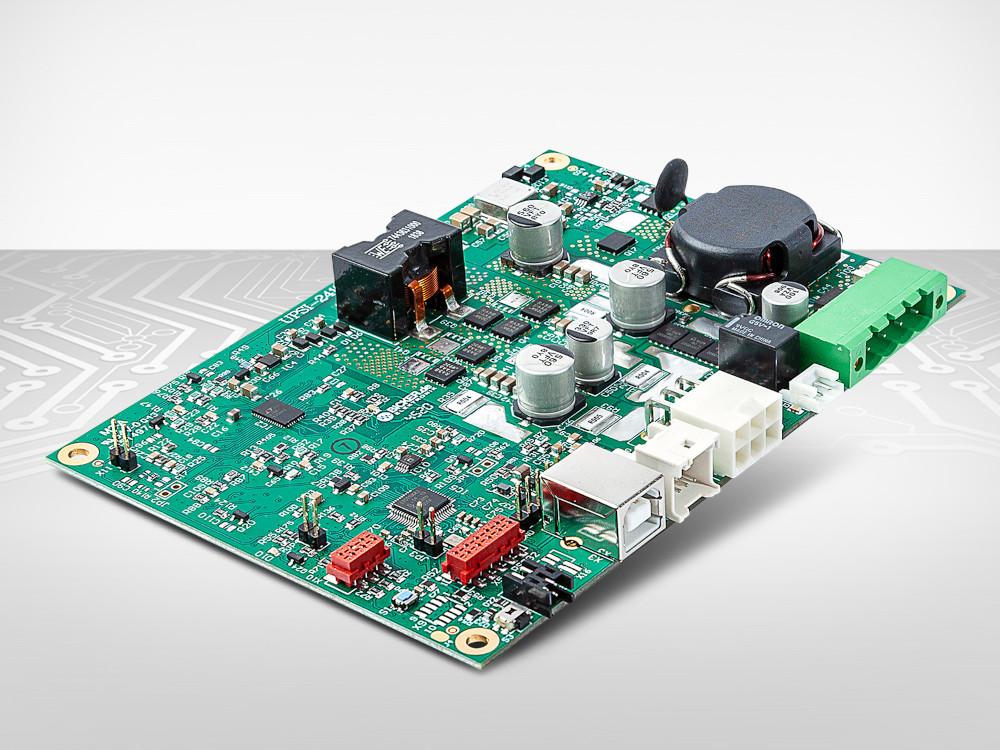

10 Sep Modular 24V emergency power supply for fail-safe systems

The intelligent DC emergency power supply UPSI-2412 in combination with suitable LiFePO4 or Supercap energy storage devices, reliably bridges power failures and brownouts, so that the uninterruptible 24 V-DC power supply of process-relevant systems is guaranteed at all times. In normal operation, the UPSI-2412 forwards the DC input voltage directly to the output, charges the connected energy storage device in parallel and monitors all relevant parameters, currents and voltages. In the event of a voltage drop or power failure, a MOSFET disconnects the input within a few microseconds and the connected load is supplied without interruption from the energy storage device and the UPSI-2412 provides a constantly regulated DC output voltage. The intelligent powersharing function at the DC input ensures that the upstream AC/DC power supply does not have to be overdimensioned, but that the input power is kept constant and distributed accordingly to the load and the charger. To ensure flexibly with different storage technologies, three charging processes with individual adjustment of the end-of-charge voltage and a charging current of up to 4.5 A are implemented: Constant Current, Constant Voltage and Constant Power. The integrated microcontroller (µC) recognizes the type and data of the Bicker energy pack, so that the charging and discharging parameters can be individually adjusted. For mobile applications, the emergency power supply has the option of starting the supplied application from the battery with a maximum load current of 7 A without a mains-side power supply being available or connected. Moreover, the UPSI-2412 has an integrated USB interface for connection to an IPC system and is recognized directly by the operating system as a UPS – without additional drivers or software installation.

Software for extended functionality and monitoring

The free ‘UPS Gen2 Configuration’ software is available for download and is used to setup and parameterize the DC UPS system as well as for real-time monitoring. The UPS and battery status displays include all relevant voltages, currents as well as battery temperature, state of charge (SOC), runtimes and cycles. The pre-programmable parameters include load sensor (mA), shutdown delay, maximum backup time, minimum load capacity before system start, ignition timer and restart delay. Self-sufficient operation is then possible with the set values. Applications comprise sensitive control and regulation systems, embedded IPCs, gateways, motors, actuators, sensors, monitoring and safety technology. According to the manufacturer, costly system downtimes and data loss can thus be effectively avoided. The DC UPS board is designed for flexible open-frame system integration in customer-specific applications and enables individual emergency power supply solutions for long-term use in Industry 4.0, medical and laboratory technology, renewable energy, control and regulation technology, safety, vision and inspection systems.

Source and image: www.bicker.de